Pragmatic Plant Manager Safety

Pragmatic Plant Manager Safety

Safety:

Excelling at safety is THE most effective way to demonstrate respect for your associates and the value you place on their contributions.

Excellence in safety creates the foundation that enables all other improvements.

This is a journey, not a destination, You are never "finished" making your work enivironment more safe for associates. However, once momentum is established, progress made and recognized, the organization can begin addressing the other priorities of the Pragmatic Plant Manager.

pragmaticplantmanager.com will be your resource for free, and fee-based, tools to lead your organization towards excellence in SAFETY.

Scroll down for additional information.

Protect the Team – Safety

Mahatma Gandhi beautifully articulates why Pragmatic Plant Managers begin their journey pursuing excellence in Safety - "Actions express priorites!" Taking immediate action, visible to the associates, establishes respect while reinforcing the importance placed on their safety and well-being.

Your safety story will evolve over time. You do not need to know precisely where you intend to go before you take the first step of the journey. This may appear to contradict other suggestions for the pragmatic plant manager around the discipline of execution, goal setting and planning. In fact, you are strongly encouraged to act before you develop your Safety Improvement plans – this is aligned with an “act, learn, plan-then-act-again” approach for continuous improvement. The first step begins with you. You will need to change your habits even if you believe you are doing many things well. Our lives change when our habits change. When associates see your routine has changed, and you are more focused on safety than yesterday, they too begin to change their habits. They see more, they inform more, they take more initiative. The entire organization begins to emulate your newly observed behaviors

.

Our lives change when our habits change. Change your daily routine to focus on Safety. Start a daily safety audit today. Plan the overall safety journey tomorrow. Change your habits today – begin (or refresh) walking the floor with the sole purpose of recognizing risks, engaging associates in correction and creating awareness throughout the organization.

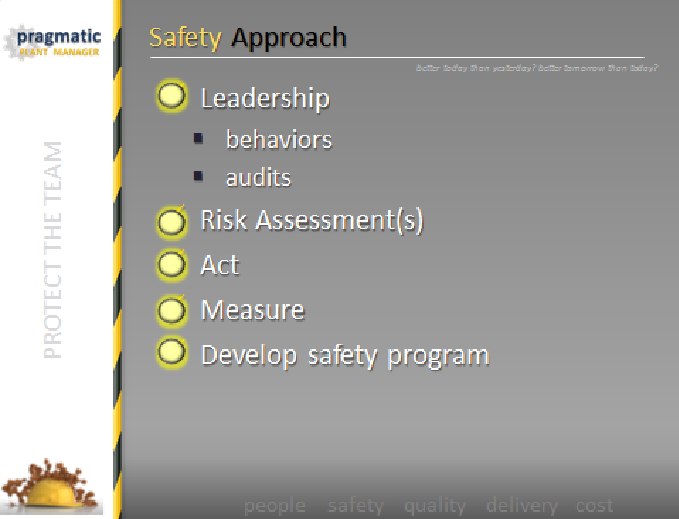

Leadership Audits:

The first step in the journey is to change your daily routine. Do not concern yourself with perfection or accuracy, what is important is a noticeable change in your habits. Your will learn as you go. Develop a checklist of safety behaviors you expect of your managers, supervisors and associates. Describe what you’d expect to see walking through a best-in-class facility that consistently goes injury- free for extended periods of time. Now act.

Block your daily schedule to assure you consistently conduct these observations. The more frequent, the more impactful your efforts will be. Remember, our lives change when our habits change. What you do every day matters more than what you do every once In a while.

While you are on the floor making your observations, talk to the associates and describe what you see. Describe what you would prefer to see and why. The ‘why’ should be centered on the health and welfare of the associate. Make a commitment to the associate that unsafe conditions will be corrected. Ask the associate for a commitment that unsafe behaviors will be improved as well. With this simple, but frequent task the first steps of the journey have been taken.

Caution:

You are doing these audits to generate Safety awareness amongst your team and model the behaviors you expect. Remember, this is the beginning of changing the organization’s DNA. This first step of this journey should not be a negative experience. Unless you observe a willful, unsafe act that puts the associate or others in jeopardy you are discouraged from pursuing formal disciplinary action. You are beginning to create an environment that instinctively surfaces risks so they can be corrected. This is not the time to instill fear.

Safety Audit Program:

The Pragmatic Plant Manager prescribes to a philosophy of “act, learn, plan-then-act again”. It’s encouraged you stay with the audit program for an extended period of time before progressing. This patience will avoid the perception these behaviors are a passing fad. Your consistency will send a clear message of the priority you place on a safe workplace. It affords the opportunity to learn what is most effective for your organization. Your learnings provide a platform to work with your staff as the program evolves.

After a few months, bring the staff together to discuss the audit approach and its impact on the organization. Document what works well, what does not and what else should be done. Use these learnings to introduce the next logical step in your journey – leadership audits. Formalize a program that requires the staff to change their habits around safety. Develop a comprehensive audit program aligned with your Safety goals and objectives. You do not stop what you started, but the audit program is enhanced with the involvement of your staff.

Momentum builds. Continue this approach for another few months before introducing additional habits. However, you are now encouraged to gain knowledge and plan for the third phase – Formal Risk Assessments, while you and your staff conduct audits and improve working conditions of your facility.

Risk Assessments:

Risks reveal themselves through unsafe conditions and unsafe acts. Unsafe conditions are the responsibility of the management team and can be corrected with little convincing. Unsafe acts require a more thoughtful approach and will take more time to impact.

Unsafe conditions generally fall into two areas: facilities / equipment and ergonomics. Facilities and equipment risks are easily identified and ownership for correction resides with the management team. Ergonomic risks require additional education for proper identification. Correction requires management’s courage to act, redesign of the operator interface to the workstation and the cooperation of associates to change behaviors. The Pragmatic Plant Manager begins the Risk Assessment phase with facilities and equipment.

R3 Risk Assessments

Risk assessments begin with a wall-to-wall assessment of your equipment for inherent risks. Corrections here will be immediately visible to the organization further establishing your sincerity and the focus on the associate’s safety and well-being. These corrections are perceived as an investment for the associate’s benefit, rather than the company’s.

Numerous, free resources exist to assist with this step in the journey. PragmaticPlantManager.com will include excel forms to download. These will be accessed from the “Tools” page, coming soon.

The process should sound familiar by now. Act. Do not worry about precision. Do some basic research (available here) and begin. Inventory your equipment to assure you eventually touch each piece. The Pragmatic Plant Manager found it best to do a wall-to-wall assessment of each piece of equipment looking for the obvious. This accomplishes two goals; it’s a visible action reinforcing your priority toward the associate’s safety and it enables you to apply limited resources to the more pressing risks that exist in your facility. You will circle back at a later date and do a more exhaustive TR3-ANSI risk assessment for each piece of equipment. Today (as opposed to the hypothetical tomorrow) you wish to demonstrate momentum for your Safety initiatives.

The Pragmatic Plant Manager has found 3 months to be a time period that establishes the new habit and enables the organization to take on new tasks. You may find this too long or not long enough for your organization. You should have invested improvements in many pieces of equipment within this 3 month window. The R3 approach allows you to establish plant-wide priorities and eliminate the riskiest conditions. Do not be prescriptive. Consider what you are trying to accomplish. An alternate approach is to select the highest risk equipment within each workgroup, This approach would expose more associates to your improvement efforts. Regardless of which approach you select to prioritize the effort, engage your associates in the risk assessments. They learn from thee exercise and you get first-hand information from the users that will prove invaluable understanding the risks that do exist.

After a few months of implementation, you will begin the next phase of risk assessments, focusing on ergonomics. This is a continuous improvement journey. Eventually, in a year-or-two, your risk assessments will be more comprehensive. The risk assessment will consider both the equipment risk and the ergonomic risk. Exercise caution moving too fast. These may be new concepts to your organization. The organization will need time to understand each new concept. Integrating too much at one time may create more learning than the organization can handle. Today, be content with the progress you are making. Recognize your organization is better today than it was yesterday. You will be better tomorrow than today – be patient.

Ergonomic Risk Assessment.

The author has been exposed to two different, formal approaches to identify ergonomic risks: The Washington Ergonomics (or WE) Assessment and the HumanTech BRIEF Assessment. Both are effective tools to accomplish your goal of reducing ergonomic risks in your operation. The Pragmatic Plant Manager found the HumanTech approach easier to grasp and engage associates in the risk assessments and corrective actions. In fact, The Pragmatic Plant Manager selected hourly associates to lead the risk assessment and improvement efforts. This provided credibility with other associates and improved their engagement when asked to change behaviors to reduce or eliminate risks.

Our experience found it best to video each operation, using the video to analyze the work content for risks. The initial assessment was then reviewed with the associates videoed to gain agreement on what was observed. This served two purposes; it validated the assessment and engaged the associate in generating improvement ideas. The associate takes ownership once they understand the risk they are exposed to. Often improvements were immediate, awareness is 50% of a solution.

Employee Engagement:

With these three initiatives – audits, Equipment Risk Assessments and Ergonomic Risk Assessments, your organization should be calibrated on risks. It’s time to engage them to lead the efforts. A few value-added approaches that would align with your safety goals are listed below.

-

Let the associates develop (5) Critical Safety Rules

-

Form a Safety Committee to lead the risk assessments

-

Appoint subject-matter-experts for both TR3-Ansi assessments and Ergonomic Assessments

-

Develop a Behavior Based Safety program let by associates.

Comprehensive Self-Assessment:

The improvement presented above is very brief. It’s likely obvious to the reader much has been excluded – fall from heights, electrical safety, confined spaces, hot work, pedestrian safety, lock-out, tag-out, powered industrial trucks, crane-hoists, emergency preparedness, personal protective equipment, and industrial hygiene to name a few.

Eventually you are encouraged to define expectations for all variables of a comprehensive safety program. Consider developing a matrix that articulates the minimum requirements for each. Expand this to include best practices and your understanding of world-class behavior. Annually, assess your operation on how it performs in each area.

Annual Safety Business Plan:

The annual self-assessment serves as mean for your team to agree align on the next steps of the safety journey. Your role leader the Safety effort steps further and further back. Safety becomes self-sustaining as you’ve engaged all levels of the organization. Allow them to develop the Safety Business plan using the self-assessment tool for insight.

You now begin your education and self-exploration toward Quality.